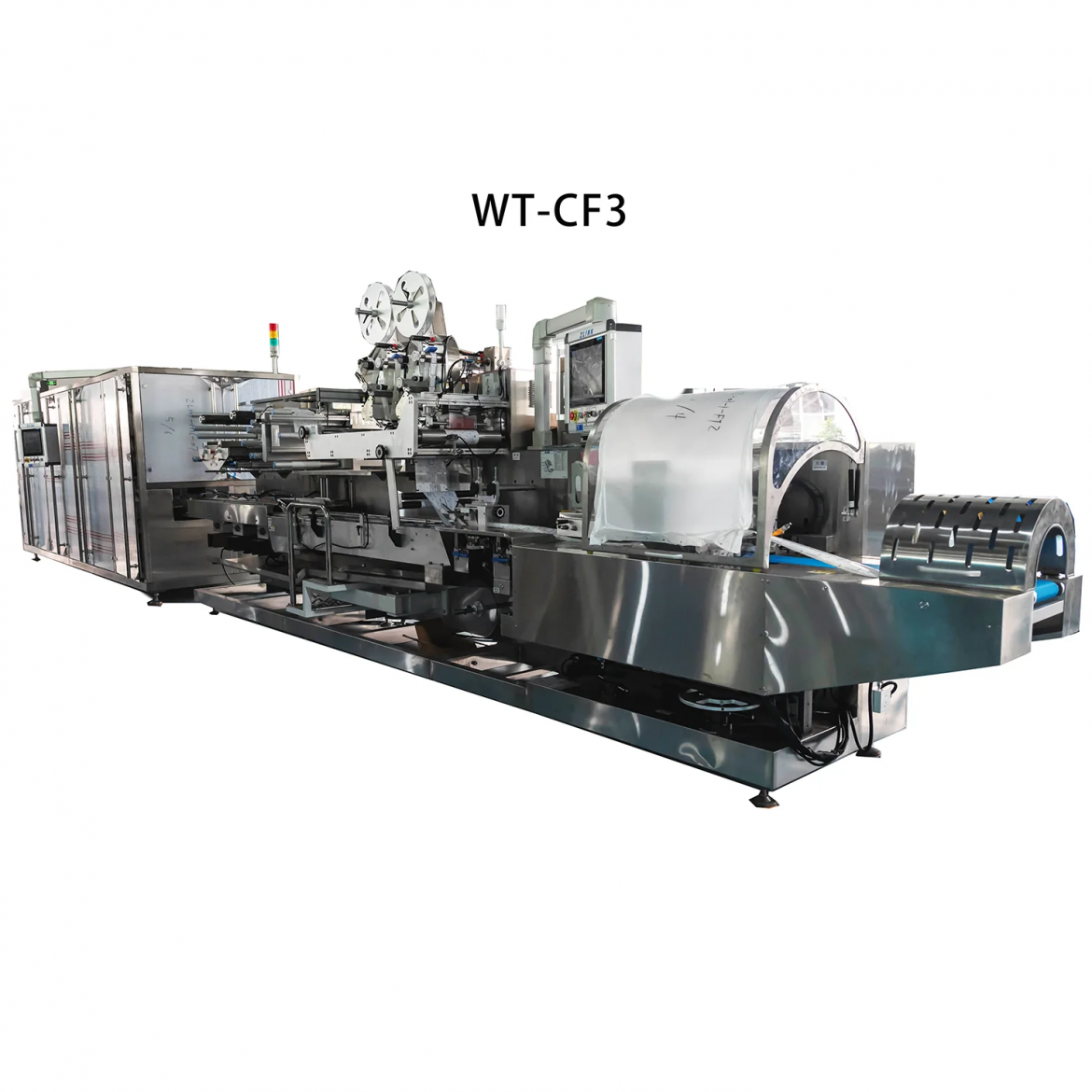

As businesses in the wet wipes industry look to scale production, ZLINK’s WT-CF3 Full-Automatic Wet Wipes Production Line stands out as a future-proof solution. Designed to meet the growing demand for high-quality wet wipes, this line is equipped with cutting-edge technology that ensures both efficiency and flexibility in production.

Advanced Technology for Future-Proof Production

ZLINK’s WT-CF3 Wet Wipes Production Line features a multi-axis servo motion controller and full servo control, making it highly scalable for future growth. These advanced systems enable precise control over the production process, ensuring that the line can handle increasing volumes without sacrificing product quality. The integration of an LCD color touch screen display also enhances usability, allowing operators to monitor and adjust settings in real-time for optimal production.

Maximizing Production Efficiency and Flexibility

One of the key advantages of ZLINK’s wet tissue paper making machine is its ability to adapt to a wide range of materials and production volumes. Features such as automatic tension control and non-stop auto splicing ensure smooth and continuous operation, even during high-speed production. With the capacity to produce up to 150 packages per minute or 1800 wipes per minute, ZLINK’s wet wipes production line maximizes production efficiency while maintaining flexibility to meet varying market demands.

Long-Term Sustainability with ZLINK’s Wet Tissue Paper Making Machine

Durability and reliability are crucial for long-term scalability, and ZLINK’s wet wipes production line is built with this in mind. The screw-type flexible cutting blade, designed for extended service life, ensures that the machine continues to operate at peak performance without frequent downtime. This robust design minimizes maintenance costs and helps sustain high-speed production over time, making it an ideal choice for manufacturers looking to scale their operations in the future.

Conclusion

With ZLINK’s high-speed wet wipes production line, manufacturers can be confident that they have a reliable and scalable solution to support future growth.