Maintaining tight control over costs, speed, and accuracy is essential in today’s manufacturing world. An auto labeling machine is a great way to simplify packaging processes and save time. The uniform and exact application of labels is essential for compliance and maintaining brand integrity. These technologies eliminate manual bottlenecks and make sure of it. With the help of platforms like PassionIOT, which offer complex control systems, these devices may be easily integrated into larger Industry 4.0 settings.

Modular Design for Operational Flexibility

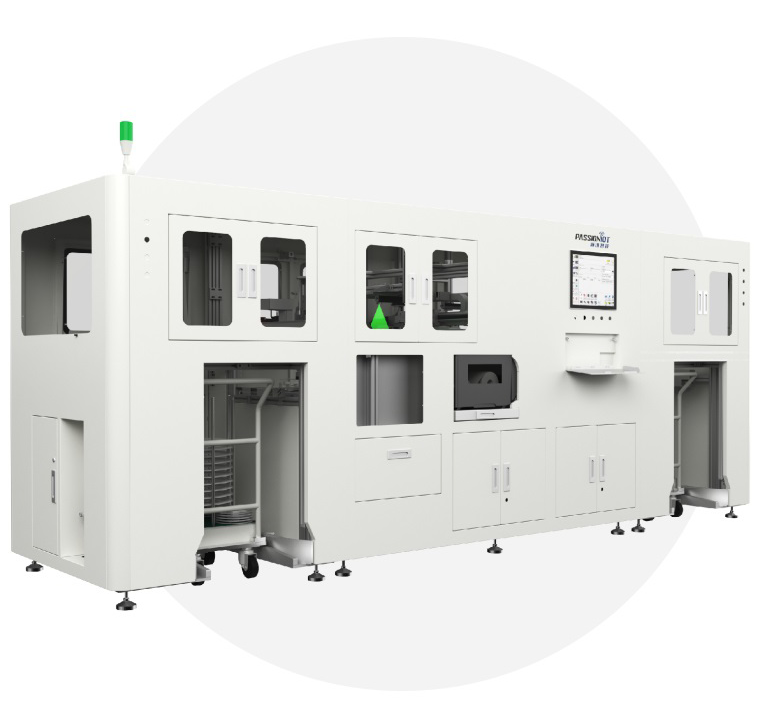

The foundation of a robust automated labeling machine lies in its construction. Machines featuring a modular design offer distinct advantages. Integrated components ensure system stability during high-speed operation, while modularity simplifies maintenance and future upgrades. This design philosophy minimizes downtime and extends the equipment’s operational lifespan, providing long-term value.

Precision Through Advanced Vision Guidance

Achieving perfect label placement every time is paramount. Modern auto labeling machine solutions utilize sophisticated vision systems combined with robotic arms. This powerful synergy enables precise detection of product position and orientation, followed by accurate label application regardless of product variations. This high level of accuracy significantly reduces waste from misapplied labels.

Seamless Integration with Production Lines

An effective automated labeling machine must integrate effortlessly with existing material handling systems. Advanced machines offer quick docking capabilities, automatically interfacing with diverse transfer methods like conveyors, turntables, or pick-and-place systems. This flexibility minimizes integration complexity and accelerates deployment.

Driving Tangible Cost Efficiency

The ultimate justification for automation is a demonstrable return on investment. Implementing an auto labeling machine directly improves labeling accuracy, drastically cuts labor costs associated with manual application, and reduces material waste. This combination delivers a compelling reduction in the total cost of ownership while enhancing throughput and quality.

Conclusion

To stay competitive in the packaging industry, it is essential to integrate a high-tech auto labeling machine that is supported by intelligent controls from PassionIOT. Silently improving accuracy, responsiveness, and cost-effectiveness, these systems are essential parts of the production machine. Production ecosystems are becoming more resilient and economically viable as a result of the shift towards such automation.