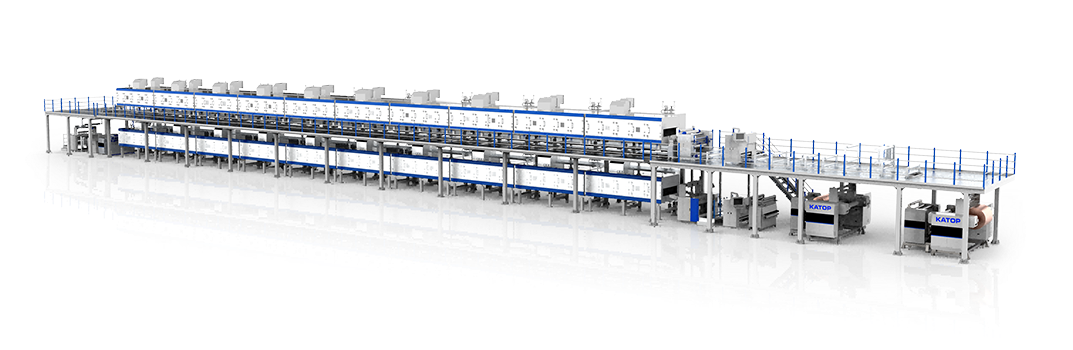

KATOP stands out among lithium-ion battery manufacturing equipment suppliers with its cutting-edge Single/Double Deck High-Speed Coater, designed to enhance precision in anode and cathode coating processes. This high-tech equipment features closed-loop thickness control, ensuring consistent coating thickness and uniformity. With roll-to-roll handling, the system ensures smooth material movement, while real-time quality monitoring guarantees that every batch meets stringent standards. These advancements are crucial for producing high-performance lithium-ion batteries, where precision in coating directly impacts the overall battery quality.

Smart Manufacturing: Intelligent and Automated Production Systems

KATOP is at the forefront of smart manufacturing with its intelligent production systems that integrate seamlessly into lithium-ion battery assembly lines. Featuring advanced technologies such as MES (Manufacturing Execution System) and AGV (Automated Guided Vehicle) linkage, their equipment enhances the efficiency and coordination of production processes. The integration of CCD closed-loop control ensures real-time adjustments to parameters, while automated maintenance systems reduce downtime and improve the reliability of the equipment. These innovations not only streamline the manufacturing process but also set them apart as a leading lithium-ion battery assembly equipment provider in the industry.

Quality and Reliability: Building Safer, More Efficient Battery Lines

KATOP’s commitment to quality is evident in its advanced monitoring systems and reliable machinery. The equipment includes surface density measurement and NMP concentration detection, which help ensure that every component meets the highest quality standards. Additionally, their design eliminates the risk of contamination with copper and metal dust by employing an anti-metal friction mechanism, further enhancing safety. The company’s energy-efficient dryer systems, optimized for heat transfer and air volume, contribute to both reduced energy consumption and improved overall equipment effectiveness (OEE). With patented designs and key components, they guarantee longevity, reliability, and exceptional production output.

KATOP: Pioneering Smart Manufacturing for Efficient Lithium-Ion Battery Production

With cutting-edge technologies, automated systems, and advanced quality monitoring, KATOP ensures lithium-ion battery production that is precise, efficient, and safe. Its commitment to innovation and reliability empowers manufacturers to optimize output while maintaining high performance standards, making them a key partner in advancing modern battery manufacturing.