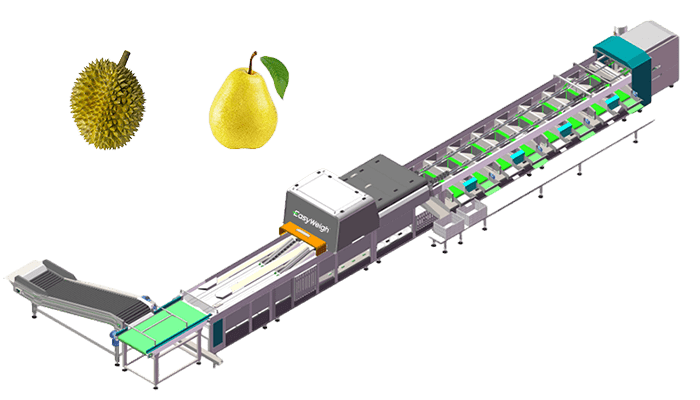

Selecting the right equipment for fruit grading can be challenging, especially when efficiency and accuracy are priorities. WEIGHT SORTING offers advanced solutions in this area, including systems designed specifically for large-sized fruits. Their optical sorting machine is engineered to examine products like Durian and Pomelo, identifying size discrepancies, color differences, and surface imperfections. By integrating high-resolution imaging with intelligent analysis, the system ensures that only fruits meeting quality standards proceed further in the production line. This approach not only improves operational efficiency but also reduces waste generated during sorting.

Key Features of Modern Optical Sorters

When assessing suppliers of optical sorting machine, attention should be given to technological capabilities. The machines from WEIGHT SORTING incorporate AI-powered evaluation, enabling real-time assessment of fruit characteristics. This allows operators to handle large volumes without compromising on grading accuracy. Additionally, modular designs and adjustable settings enhance adaptability for different fruit types and varying production scales. Suppliers who provide clear information about these features, along with responsive customer support, often offer more reliable solutions for long-term operations.

Comparing Supplier Support and Services

Beyond the technical specifications, support and service play a crucial role in the selection process. Companies like WEIGHT SORTING provide guidance on installation, calibration, and maintenance, which are essential for consistent performance. Evaluating whether a supplier offers comprehensive training and accessible service channels can be as important as examining the machinery itself. Optical sorting machine efficiency can be significantly influenced by ongoing technical support, especially in high-throughput environments handling large fruits.

Making an Informed Choice

Choosing the right partner involves balancing machine capabilities with practical service considerations. The systems from WEIGHT SORTING demonstrate that advanced imaging and AI analysis can optimize fruit sorting processes while maintaining quality standards. By carefully reviewing product functionality, supplier experience, and after-sales support, businesses can make informed decisions that align with both operational requirements and product quality expectations. Selecting a supplier who emphasizes precision, efficiency, and support can lead to smoother production workflows and reduced operational challenges.