On September 10th, the Logis-Tech Tokyo 2025 (LTT) officially opened at the Tokyo International Exhibition Center. SEER Robotics, themed “Make In-House Robot Development Easier,” showcased a one-stop robot development solution, two main overseas robot products, robot scheduling systems, and a series of visualization products at booth 7-507 at the Expo logistics.

Through real-scene dynamic demonstrations and multi-terminal interactions, SEER Robotics fully presented its core technologies and ecosystem layout in the field of intelligent robots.

3D Interaction, Creating a Visual Factory

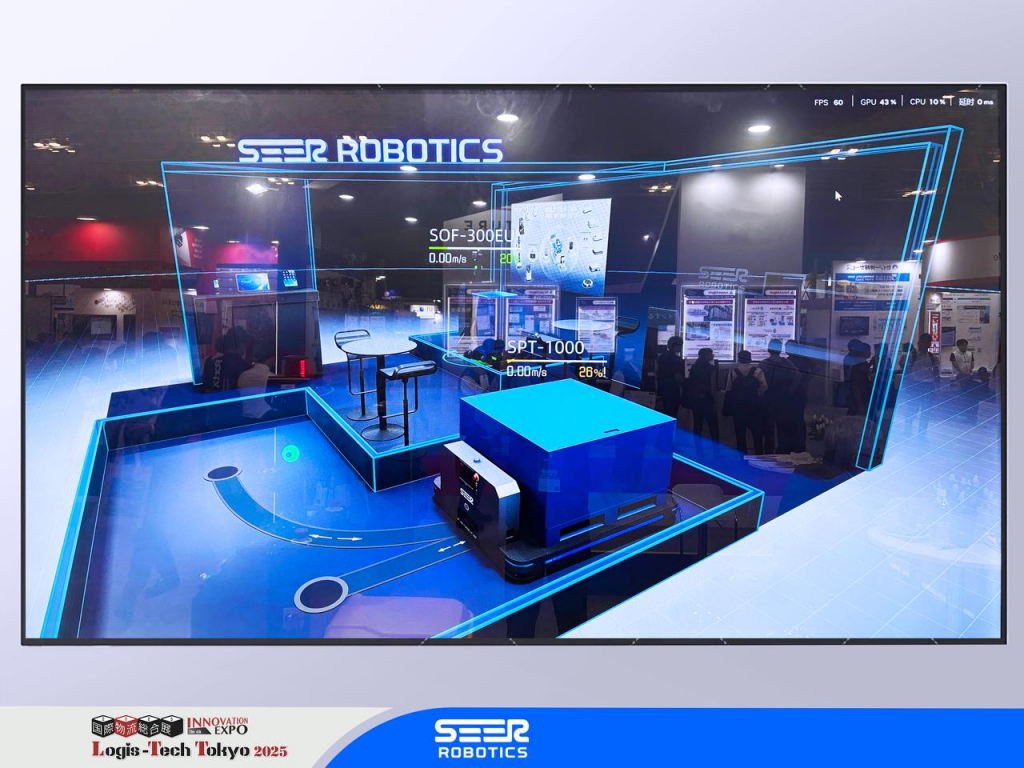

The robot fleet management software exhibition area was a major highlight of SEER Robotics’ booth at this Tokyo Innovation Expo. Based on the 3D robot visualization map Meta-Map Pro, a high-precision 3D exhibition scene was built, providing users with a game-level visual experience and smooth interaction.

Through Meta-Map Pro, the audience on-site could view the two robots, SOF-300EU and SPT-1000, in real-time, displaying key indicators such as goods information, path planning, and equipment data. Currently, these products have been used in the factories of many mechanical manufacturing and 3C electronics industry customers in China.

SEER Robotics’ visualization product series also includes the 2D robot visualization map Meta-Map and the 3D digital twin Meta-World. The full-range products highly reproduce the real-world factory environment, achieving precise presentation of multidimensional data and millisecond-level response. This helps enterprises build an efficient visualization information platform and supports the construction of digital factories.

Unified Scheduling, Global Coordination

The scheduling RDS system was also exhibited at this Tokyo Innovation Expo. This product supports unified management of all robots within a factory and various types of automated logistics equipment. It enables unified robot schedule and management of multiple robots, different models, and multiple areas, achieving dynamic global coordination planning.

RDS system has strong multi-terminal compatibility, allowing users to switch seamlessly between different devices such as smartphones, tablets, and computers, realizing a truly cross-platform, smooth experience. The product also supports secondary development, enabling customers to DIY according to their businesses and implement scheduling solutions that are more adapted to production.

Focusing on Scenarios, Innovative Robot Products

At the Expo logistics, SEER Robotics brought live dynamic demonstrations of two star products in the international market, including the E-type closed-pallet-handling automated forklift SPT-1000 and the single-arm intelligent forklift SOF-300EU. These demonstrations vividly showed SEER Robotics’ innovation and application capabilities in complex and niche scenarios.

- SOF–300EU: Benchmark Application for Compact Forklifts

SOF-300EU automated forklift simulated the unmanned handling process of infectious medical waste, demonstrating its excellent performance in high-standard medical environments. Its body width is only 1/3 of that of a regular intelligent automated forklift, giving it strong adaptability to various scenarios and the ability to flexibly deal with the narrow and complex passages in hospitals.

Equipped with AI deep-learning algorithms, it can intelligently recognize the outline of racks and accurately pick up goods without manual parameter settings. It achieves full-process automation from handling, disinfection, to storage, greatly reducing the workload of medical staff, effectively lowering the risk of cross-infection, and enhancing the safety and controllability of medical waste transportation.

- SPT–1000: Innovative E–Type Patent Design

SPT-1000 automated forklift demonstrated its ability to accurately pick up target pallets. With AI image-based adaptive recognition technology, it can make real-time posture corrections and support customized size recognition, compatible with pallet standards from multiple countries.

This model is equipped with four-corner obstacle-avoidance lasers for all-around safety. It supports optional 2D/3D navigation solutions and can be widely adapted to diverse scenarios from ordinary warehouses to ultra-narrow aisles.

SRC Controller: The Strongest Robot Brain

As a core product of SEER Robotics, the booth at Logis-Tech Tokyo fully displayed the module products needed to develop robots based on the safety-type robotics controller SRC-3000FS series.

The SRC-3000FS innovatively integrates an all-in-one safety PLC. Through dual optimization of hardware structure and software algorithm iteration, it achieves multidimensional breakthroughs in higher integration, more compact space, and lower overall cost. Its forklift-specific version is equipped with double computing power to support stable robot operation in complex environments. It also introduces new calibration technology that can automatically identify unqualified calibration items, shortening the traditional 2-hour calibration process to 30 minutes and greatly improving deployment efficiency.

The robot development wall centrally displayed some accessories of the three major modules: perception, execution, and energy. There are more than 300 accessories available online, all of which have been fully adapted to the SRC series robotics controllers and are plug-and-play. This completely solves the industry pain points of long robot development cycles, high customization costs, and difficult accessory selection in the past.

In addition to this, the one-stop robot development solution also includes the entry-level controllers SRC-880 and SRC-1000 series, the general-purpose controllers SRC-2000 series, and the embodied intelligence controllers SRC-5000 series, supporting rapid development from traditional intelligent robots to the latest humanoid robots.

Outstanding Product Strength, Chosen by Over 1500 Global Customers

As the world’s largest intelligent robot company with robotics controllers at its core, SEER Robotics has occupied an important position in the global robot market with its excellent technical strength and forward-looking layout. It has achieved the global first place in robotics controller sales for two consecutive years from 2023 to 2024. It also took the lead in building the world’s first large-scale intelligent robot open platform, continuously promoting industry ecosystem innovation and technological progress.

At present, SEER Robotics’ products and services have successfully entered more than 65 countries and regions worldwide, serving over 1500 customers. These include many world-renowned enterprises such as Siemens, FAW-Volkswagen, Samsung, Walmart, Opple, Haier, and Colgate, covering a wide range of fields including industrial manufacturing, consumer electronics, medical, and retail. This trust is not only due to its leading technology and product strength, but also thanks to SEER Robotics’ deep understanding and continuous empowerment of customer scenario needs.